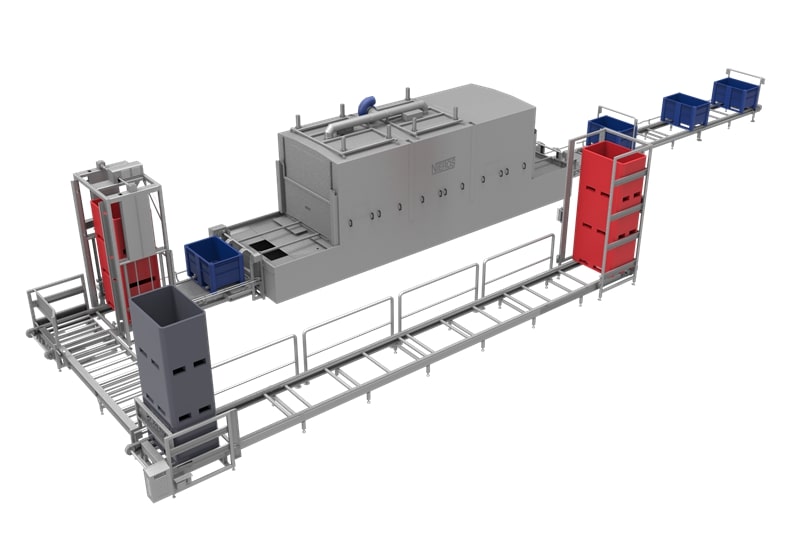

Tunnel washer system helps companies optimize every aspect of production, which is crucial in today’s fast-paced industrial environment. It is one of the most effective ways to enhance efficiency and ensure top-tier cleanliness. These systems are essential in various sectors, offering numerous advantages from enhanced sanitation to improved operational efficiency.

A tunnel washer system and a drying tunnel for crates are invaluable assets for companies looking to enhance their operational efficiency and hygiene standards. When searching for a tunnel dryer for sale, focus on material quality, energy efficiency, capacity, automation features, and maintenance support. Investing in these systems can lead to significant long-term benefits, including enhanced cleanliness, increased productivity, and substantial cost savings. Various sectors, from food processing to pharmaceuticals and logistics, can greatly benefit from these advanced cleaning and drying solutions, making them a recommendable investment for any business looking to optimize its operations.

What is a tunnel washer system?

Tunnel washer system is a highly efficient, continuous cleaning solution designed to handle large volumes of items such as crates, trays, and other reusable containers. These systems automate the washing process, ensuring that each item is thoroughly cleaned and sanitized. The process typically involves multiple stages, including pre-washing, washing with detergent, rinsing, and sometimes disinfecting. This meticulous process ensures that all contaminants are removed, making the items safe for reuse in food processing, pharmaceuticals, and other industries where hygiene is paramount.

Where to find a tunnel dryer for sale?

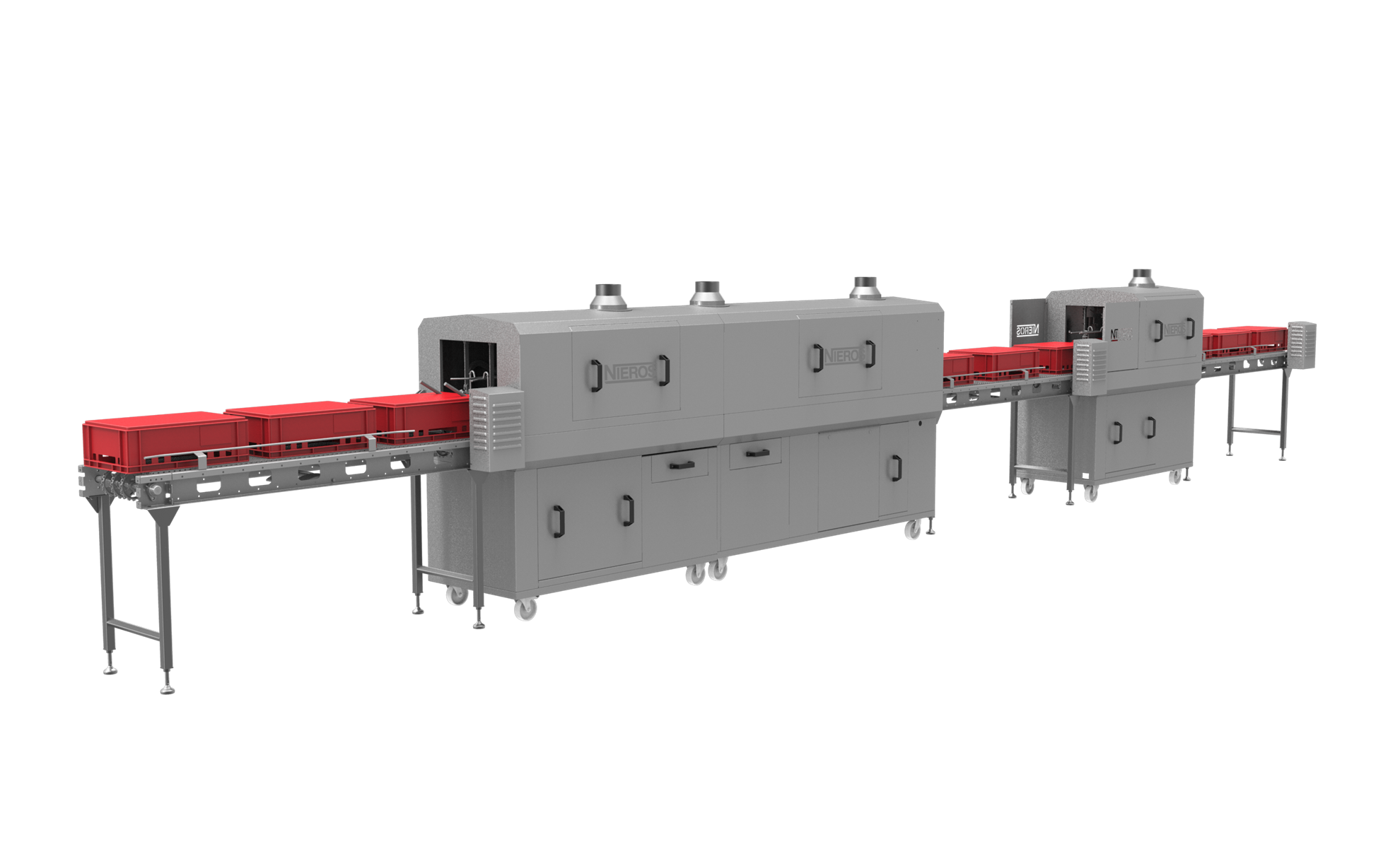

When searching for a tunnel dryer for sale, it is important to consider reputable manufacturers and suppliers who specialize in industrial cleaning and drying equipment. Leading suppliers often have extensive catalogs and can offer customized solutions tailored to specific industry needs. Websites of established manufacturers and industrial equipment distributors are excellent places to start. Additionally, industry trade shows and exhibitions provide opportunities to see these systems in action and speak directly with vendors about your specific requirements.

Nieros stands out as the best and most advisable manufacturer due to the exceptional quality, innovative technology, and unparalleled customer support. The durable, efficient, and reliable systems ensure optimal performance and longevity.

Key traits to look for in a tunnel dryer for sale

When evaluating a tunnel dryer for sale, several factors should be considered to ensure you select the best system for your needs. The construction material of the tunnel dryer is crucial. Stainless steel is often preferred due to its durability, resistance to corrosion, and ease of cleaning. Ensure the dryer is made from high-grade materials that can withstand continuous use and harsh cleaning agents.

Look for systems that offer energy-saving features. Efficient tunnel dryers reduce operational costs and have a lower environmental impact. Consider the volume of items you need to dry daily. Ensure the dryer can handle your workload without causing bottlenecks in your production line.

Advanced dryers come with sophisticated control systems that allow you to set precise drying parameters. Automation features reduce the need for manual intervention, increasing efficiency and consistency. Choose a tunnel dryer that is easy to maintain and comes with robust customer support. Reliable after-sales service ensures minimal downtime and swift resolution of any issues.

Benefits of a drying tunnel for crates

Investing in a drying tunnel for crates offers numerous benefits to companies across various sectors. Properly dried crates are less likely to harbour bacteria and other contaminants. This is particularly crucial in the food processing and pharmaceutical industries, where hygiene standards are stringent. Automated drying tunnels streamline the drying process, reducing the time and labour required compared to manual drying methods. This leads to faster turnaround times and higher productivity.

Drying tunnels provide uniform drying, ensuring that all crates are dried to the same standard. This consistency is vital for maintaining product quality and safety.

While the initial investment may be significant, the long-term savings on labor, water, and energy costs can be substantial. Additionally, automated systems reduce the risk of human error, which can lead to costly contamination issues.

Sectors that can benefit from a tunnel washer system and drying tunnel for crates

Several sectors can significantly benefit from implementing a tunnel system and drying tunnel for crates. Cleanliness is paramount in food processing. These systems ensure that all equipment and containers are thoroughly sanitized, preventing contamination and ensuring compliance with health regulations. Hygiene and precision are critical in pharmaceuticals. Tunnel washer systems and drying tunnels help maintain the high cleanliness standards required for manufacturing and packaging.

In sectors where reusable crates and containers are prevalent, such as logistics and warehousing, these systems ensure that all packaging materials are clean and ready for reuse, improving operational efficiency and product safety.

Parts and components often need to be cleaned to precise standards before assembly. Tunnel washer systems ensure that parts are free of contaminants, which is essential for the performance and longevity of automotive products.